Have I got Safety Glass?

Safety Glass

Toughened safety glass! You can not drill a hole In Tempered Glass? Tempered glass, also known as safety glass, is engineered using thermal and chemical processes to give it added strength. The glass is compressed on the outside and also compacted in the center, so when it breaks, it shatters into tiny pieces to cause minimum damage. This is why tempered glass is known for both its strength and safety. It is not possible to drill a hole in tempered glass. It would completely shatter as soon as the drill comes into contact with the glass. If you need a hole in the tempered glass, it needs to be done before the process of tempering. Thin layers of tempered glass, for example, protectors for mobile phone screens, can be cut with industrial lasers. However, this can only be done industrially and not at home or in a local shop. Thicker and larger products of tempered glass are still drilled and cut for desired shape and design before the tempering process because, after the tempering, it is not possible. Why You Can1t Drill a Hole in Tempered Glass Tempered glass is manufactured in a way that, if it breaks, it will crumble into tiny granular pieces. It does not break like typical glass, which shatters into dangerous and sharp shards. This is why it is difficult to drill a hole into it because it is meant to be a safety glass that will not break easily, and if it does break, it will not have perilous concerns. It is engineered in this way to distribute the pressure throughout the piece. This is when we see a tempered screen protector break. Web-like cracks appear throughout the screen, not just on the area where the damage was done. Tempered glass is durable and therefore used in everyday products which could cause harm if shattered, for example, car windows, shower cabins, glass doors and tables, some cookware and microwavable objects, and of course screen protectors. How to Tell if a Glass is Tempered? It can be tricky, but tempered glass has many indications to prove its authentic material. There are several ways to check whether a glass is tempered or not. If none of these ways help to show whether the glass is tempered or not, then it is likely that the glass you are checking is not tempered. Smooth Edges Are a Sign That the Glass is Tempered Tempered glass has a smooth finish on the edges of the sheet. Rough edges mean that the glass is not tempered. The rough edges will look visibly uneven and also feel coarse on touch. How to Drill a Hole in Other Forms of Glass Even though tempered glass cannot be drilled or cut, other forms of glass can. Drilling a hole in glass requires a few careful steps. The equipment required is a drill and glass drill bits. Diamond drill bits can also be used and give a smoother finish. They also cause less breakage as compared to carbide drill bits. It is best if the drill you buy can change its speed. Once your drill is in place, you`re ready to go. First and foremost is safety. Before working with drills or wet tile, saws make sure to wear safety gloves and glasses to protect from any cuts from shards or pieces of glasses reaching the eyes. Wearing a mask is also recommended since glass dust can be breathed in and prove hazardous for health. It is important to note that drilling can incur heat production and burn the glass. Therefore, apply some moisture for coolness before starting the drilling process or place a wet cloth under the glass to keep it from heating up.Before starting to drill, the glass you are working on needs to be placed on a stable place, and it is better if it is attached to something when placed on the work table (for example, cardboard or a rubber pad), so it does not slip when drilled. Increase the Speed of the Drill Gradually The drill being used should be first operated a slow speed to create a small dent in the glass where the hole is to be drilled. After that, you can remove the material (cardboard or rubber pad) that was used to stabilize the glass from underneath and then drill the hole at a faster speed, The best way to buy tempered glass is to purchase it in a shape or size that you are planning to change it into later instead of buying it with a mindset of working on it at home. It is engineered with the intention of safety and strength; therefore, it is not meant to be cut and drilled into. S EN 12150-1:2000 Thermally toughened Safety Glass for use in buildings How to tell - Toughened Safety Glass! “Toughened” or “tempered” or simply “safety” glass is, as these names suggest, much more resistant to knocks and bumps than regular glass. It is manufactured by way of a slower cooling process, and as a result, is considerably more robust than standard panes of glass. But how would you determine whether a pane of glass is? “regular” or tempered safety glass? Of course, the “proof is in the pudding”, in that, if you smash it, it will fracture into thousands of tiny pieces and remain, as far as possible, in the shape of the pane. But this is not a practical or advisable way of answering this quandary. So how else can you tell Safety mark This is the most straightforward way of working out if a pane is made of safety glass or not.

The manufacturer’s logo and name should be present, alongside reference to the relevant product standard. In the UK, these standards are:

BS EN 14449 – to identify laminated glass (annealed) BS EN 12150 – to identify as toughened glass BS EN 14179 – to identify heat soaked, thermally toughened glass.

Kitemarks

–

The Kitemark symbol of quality was

first conceived in 1903 to identify

glazing solutions that were at the

pinnacle of safety and reliability.

Today, glass kite marks remain as

one of the oldest product quality

marks in the world still in use.

As the UK’s leading laminated glass supplier, safety is at the forefront of everything we do. Since our establishment in the 1970’s, our own history has been closely intertwined with the Kitemark symbol of quality – so much so that it holds provenance within our own name.

All of our glazing solutions demonstrate the quality assurance of BSI certified Kitemarks , as listed below.

|

BS EN 12150-1:2000

|

|

BS EN 1863-1:2011 Heat strengthened, soda lime silicate glass for use in buildings |

||

|

BS EN 14179-1:2005 Heat-soaked, thermally toughened soda lime silicate safety glass for use in buildings |

|

BS 857:1967 Safety glass (toughened or laminated) for use in land vehicles , including road vehicles and railway |

||

|

BS EN 14449:2005 Laminated glass and laminated safety glass for use in buildings |

||||

WHY CHOOSE US

We are constantly improving our kits to benefit our customers with better results for longer time

HOW TO

Every Window Repair kit receives an easy to follow installation guide & has access to our popular You Tube tutorials

Support

We aim to to please our customers offering them support with our tutorial videos on You tube

How does it all work

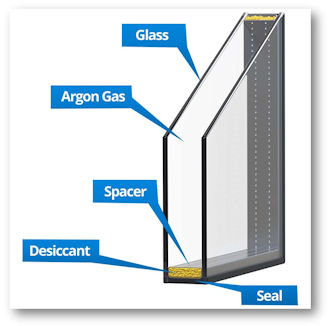

Double glazing refers to a window that has two panes of glass. The main component of the window is the double-glazed sealed unit, also known as an insulated glass unit (IGU) which sits in a frame of uPVC, aluminium, or timber. The IGU comprises of two sheets of glass separated by a spacer bar to create an air gap which is filled with an insulating gas. A bit like a sandwich of glass bread with a filling of air. The primary benefit of double glazing is thermal insulation – to retain heat in a room whilst stopping cold air entering from outside to make the room more energy-efficient. Double glazing windows make such a difference to energy-efficiency that building regulations were set in 2002, to say that all replacement windows must be a minimum double-glazed C rated – unless the property is a listed building or in a conservation area.

It might be difficult to remember a time before double glazing as most houses today have upgraded their windows to be more energy efficient. But, once upon a time, we all lived in houses with cold rattling windows. There's a variety of claims on who was the first to experiment with double glazing, but it's generally considered that the Scottish were the first in Victorian times. Adding a second pane of glass to their existing windows to try and keep out the harsh Scottish elements. Although, there is mention that the Romans also had their own heat retention system. Commercially, double glazing was 'invented' in the US in 1930 by a CD Haven and this was later patented as 'Thermopane' by an Ohio glass company. After this, in the 50s, double glazing began to filter into the homes of Americans. In 1965, in the UK, Everest began life selling a version of aluminium secondary glazing. In 1978 when we developed our first aluminium double-glazing product. In 1984, our uPVC double glazing was created, and this quickly became the window of choice for the UK

Double glazing works by creating an air gap that insulates against heat transfer between two different temperature zones (inside and outside). Two panes of glass are sealed in a unit (IGU) separated by a spacer bar. The space between the panes (usually 6-12mm) creates an air gap that slows down thermal transfer (hot or cold) by conduction – it doesn't 'trap heat' but it slows down the movement of heat to reduce heat loss. Because air can't circulate in the narrow gap between the panes, air convection is slowed down and this also reduces heat transfer.

Double glazing reduces heat loss through the thermal cushion and insulation of the air contained in the sealed unit. As cold air hits the external pane of glass, the pane of glass transfers the temperature to the Argon gas layer. Argon gas has a 34% reduced thermal transfer rate to air and slows down the conduction of heat between two differing temperatures. So, the Argon layer transfers less of the temperature difference to the internal pane of glass which remains at a median temperature between the Argon glass and the room. In the same way, when the warm air from the room meets the internal pane of glass the Argon gas slows the transfer of the warmth from the inside out. And heat is retained in the room. In a double-glazed unit, the outside pane of glass and the internal will be different temperatures.

Sound is an energy that moves in waves, like waves on the sea, by vibrating the molecules of the air and objects it comes in contact with. When sound waves hit glass, the glass vibrates at the sound wave frequency and transmits the vibration to the air molecules on the other side of the glass. As the sound wave travels, dense objects absorb the energy which reduces the frequency of the waves as it passes through. This is why, if you put your ear to a wall you can hear people talking on the other side but if you step away from the wall you can’t hear it. Sound has a longer wave vibration than light which means it can bend (diffract) around corners making it far more difficult to contain than light. If you have a trickle vent, you can still hear a lot of noise even if your window is closed. It also means, if the seals are failing in the double-glazed unit, you will hear an increase of noise leaking through the window. Double glazing reduces noise by absorbing some of the energy and slowing down the vibration frequency as it transfers through the glass and the layer of Argon gas. When the sound wave passes through the other side of the window, the sound wave is slightly diminished and the noise a little quieter. However, the key to reducing noise as much as possible is to disrupt the sound waves and frequencies as they pass through a material. This can be done by combining different thicknesses of glass close together.

The air around us is full of tiny molecular droplets of water that are invisible to the eye. In warm air, the molecules are spaced far apart which holds the moisture but as the air cools the molecules come together. When the molecules are so close together, they merge into visible liquid this is known as the 'dew point'. Condensation manifests when moisture-laden air comes in contact with a cold surface – such as a windowpane. When you boil a kettle, cook food or have a hot shower, the air becomes filled with more moisture than usual and this is why kitchen windows and bathroom mirrors are most steamy. We also expire moisture on our breath and this is why you find condensation on a bedroom window when we wake up. Inside the double-glazed sealed unit, the contained air also holds a low level of moisture that could form on the glass if the temperature difference should change. To address this, every sealed unit is built with crystalline desiccant (like what you find in a new bag or shoes) contained in the spacer bar. The desiccant draws the moisture out of the air gap and keeps the internal space between the panes dry. Internal condensation happens when the seals on the sealed unit begin to fail and more moisture is drawn into the unit. The desiccant becomes saturated and can no longer hold moisture and as a result, condensation forms inside the unit. The reason we see so much condensation on single glazed glass is that the glass is susceptible to cold and stimulates the dew point from the water vapour in the air. Double glazing helps to reduce condensation on the inside of your windows (inside the room) because the glass is not as cold as single glazed. The air gap inside the double-glazing sandwich helps to keep the internal pane of glass closer to room temperature. This difference in temperature is enough to stop the water vapour reaching dew point and forming condensation on the glass.

Double glazing reduces heat loss and acts as a barrier against the cold but it doesn't stop the warmth from the sun, known as solar gain. Sunlight produces short wave infrared radiation – this is what warms objects in the sunshine. The short waves are absorbed by glass from the outside and the energy becomes re-radiated from the inside of the glass as long-wave infrared. Short waves can pass through glass but the long waves can't, so the thermal energy of the infrared radiation becomes trapped bumping against the glass unable to pass through. This process is known as the greenhouse effect. The rise in temperature is known as solar gain – we measure this by G value. For windows facing direct sunlight, we recommend low-emissivity glass (Low-E) that help to regulate room temperature because rooms quickly overheat with solar gain. If you've ever sat in a conservatory on a sunny day you will know how oppressive it can get. Low-e glass applies a microscopic magnetron coating that reflects the shortwave radiation away from the outside of the glass. The window maintains the clarity of daylight but stops the build-up of thermal energy and the greenhouse effect. Low-e glass can also be combined with a solar control glass coating that further filters the light to reduce the solar glare and reduce damage to furnishings and fabrics.

The sealed unit is an integral part of the double-glazed window and the part most susceptible to failure. This is where manufacturing quality really counts. A double glazed unit is created by cutting the two panes of glass to size The spacer bars are prepared to size with the desiccant inside. Old aluminium spacer bars are conductors of temperature and act as thermal bridges transferring the cold from the outside pane to the inside. This is why the edge of the glazed unit has always been the weak spot where it's the coldest. Warm edge spacer bars are blended from stainless steel and polypropylene which has a low thermal conduction rate and this reduces heat loss at the edge of the sealed unit. One pane of glass is laid with the spacer bars in position. This moves through our Argon filled chamber and whilst moving, the second pane of glass is precisely pressed on top, sealing the unit and trapping the Argon. We construct our units by a robot in an Argon filled chamber to ensure the only thing in our sealed unit is Argon. Other companies drill two holes into the frame and hand pump the Argon which can leave the unit filled with a mixture of air and Argon. By not drilling the frame we maintain the structural integrity and airtight seal of the frame. The unit is then sealed with a bitumen-based sealant around the edge. We apply the sealant in a molten state so that it flexes if the unit does and keeps the unit airtight. Lifting glass by hand puts unnecessary stress on the pane that can lead to warping and visual defects. We assemble our units mechanically so that panes are lifted evenly using suction cups to ensure no part of the glass is placed under stress to maintain integrity and quality. The double-glazed unit is then ready for assembly in the chosen frame material.

Thermal transfer, solar gain, dew point, sound frequency and conduction - what all this information means in reality is that double glazing will: Keep more external noise out of your homeRetain more heat and keep your home warmerReduce condensation on your windowsReduce the amount of energy you use to heat your homeReduce your energy billsAdd value to your homeIf you’re thinking of upgrading your windows, all our windows are bespoke made from a range of different glass products. If you have an extra cold room that doesn't get light, a room that gets too much sun, or a bedroom facing a noisy road – we can make the perfect window for you.

Support

Why condensation forms Between a failed Double-glazing Unit When condensation between double pane windows forms it means the seal on the insulated glass unit has failed. In this situation, why replace the unit when you can fix it? How Insulated Glass Works With double pane windows,

Read more.

As the sun shines down on your windows, the glass expands and puts pressure on the seal. Overnight, the glass cools and shrinks. Day after day, this process repeats, and, over time, the seal may fail. Windows on the south and west sides often fail before others since they receive the most sunshine.

Read more.

How to tell - Toughened Safety Glass! “Toughened” or “tempered” or simply “safety” glass is, as these names suggest,much more resistant to knocks and bumps than regular glass. It is manufactured by way of a slower cooling process, and as a result, is considerably more robust than standard panes of glass.

Read more.